This know-how extends to elements specific to stacks (fluid circulation, sealing...), and to complete systems (auxiliary components, operating conditions, and safety...). Our customers are supported by our experts at all stages of their project, from analysis of needs, and co-writing specifications, to product development, and the eventual transfer of skills required for production start-up.

轴上's engineering services for fuel cell design

Our engineers are experts in the design of stacks and fuel cell systems for a variety of application areas. This unique know-how attracts companies including one of the world leaders in fuel cells for forklift trucks to partner with our teams in developing a new range of fuel cells for the European market.

寻找表演?改善寿命?解决可靠性和安全问题?优化生产成本?

我们的设计办公室可帮助您定义技术规格,在技术选择中借鉴专业知识。

我们的设计办公室可帮助您定义技术规格,在技术选择中借鉴专业知识。

Your project benefits from state-of-the-art testing facilities at ourSassenage测试中心.

Your project benefits from state-of-the-art testing facilities at ourSassenage测试中心.

You benefit from the safety guarantees and access to hydrogen in large quantities that only a group such as Air Liquide can provide.

You benefit from the safety guarantees and access to hydrogen in large quantities that only a group such as Air Liquide can provide.

Looking for a service provider to test your products? To acquire test benches?

Our teams take charge of testing products you have developed at our Sassenage test centre.

Our teams take charge of testing products you have developed at our Sassenage test centre.

We can design and manufacture test benches adapted to tests required for your products.

We can design and manufacture test benches adapted to tests required for your products.

Stages of project development in partnership

Co-construction of technical specifications

Our engineers analyse your needs, a fundamental step for your project. Knowing how to identify the fundamental characteristics is crucial to guarantee the efficiency and profitability of your product. What are your priorities? Fuel Cell lifetime, compactness, performance, reliability, production cost?

At each stage our design office provides the advice you need to make the best decisions, which we then incorporate together in your specifications.

定制产品设计(堆栈,系统,长凳)

Throughout this process, our experts subject your products to several tests that evaluate their performance, reliability and suitability in accordance with your specifications.

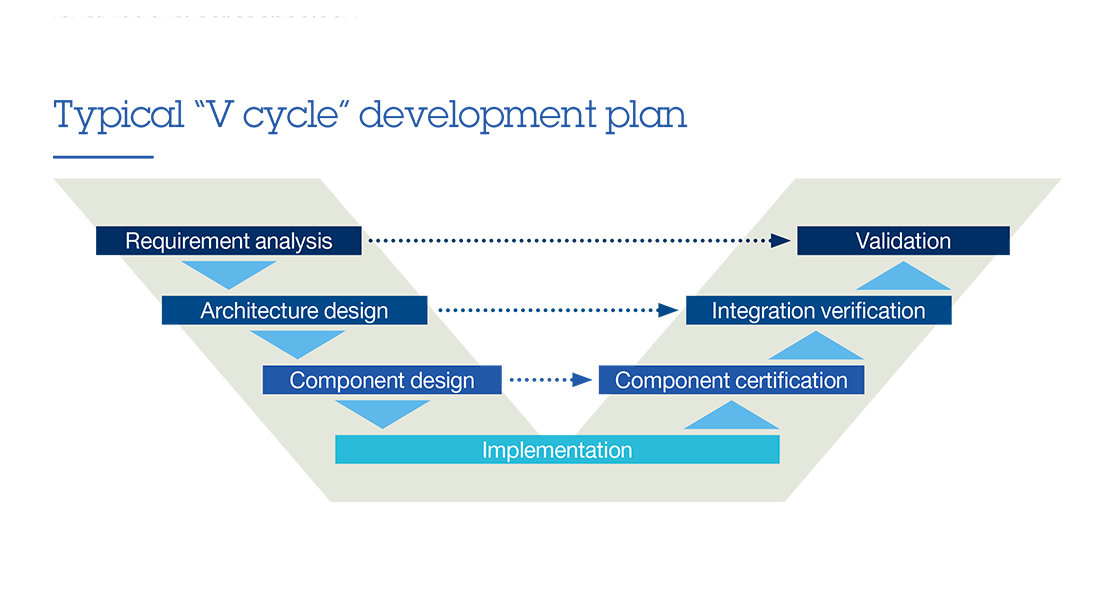

Our project management method – Cycle V – results in a high-performance product based on quality design.

Preliminary design

To define the system architecture, we study the structure of the fuel cell system, draw up the functional architecture diagrams and measure potential risks.

Detailed design

At this stage, our experts design the detailed drawings of the stacks and fuel cell systems. This work includes the specification of all materials and components of the assembly, as well as the tools and software required for its implementation.

We validate the technical hypotheses and perform the necessary calculations for the brief, with certain elements prototyped. For example, sub-component testing allows us to validate hypotheses and identify potential problems, with the aim of reducing the level of risk and uncertainty. In this way, our experts can ensure that production complies with specifications and decide to proceed with the assembly of your system or stack.

Prototyping

Prototyping is to validate whether your fuel cell system confirms with specifications such as:

- Electrical performance

- Mechanical characteristics

- Reliability

- Lifetime

- Manufacturing cost.

The prototype is subjected to multiple tests at our dedicated site in Sassenage. Our teams can then manufacture pre-series for testing of your products in real-life situations.

Transfer of skills

我们的合作可以随着技能转移给您的团队,让您在完全自治中操作氢燃料电池系统的制造。

Fuel cell: how does it work?

For 1 to 120 kW cells, Axane uses PEM (proton exchange membrane) technology. Through an electrochemical reaction, the cell produces electricity and heat while only emitting water.

The fuel cell consists of several cells, each containing a membrane electrode assembly (MEA), which is the active heart of electricity generation. The MEA consists of two electrodes, the anode (negative) and cathode (positive), on either side of the PEM membrane.

At the anode, H2hydrogen molecules are transformed into H+ ions (protons) and electrons. The H+ions are directed to the cathode through the PEM membrane. At the cathode, they react with oxygen and electrons to form water. The production of electrons and their consumption generate the expected electrical current and power.

The electrochemical reactions at the electrodes are:

at the anode 2 H2→ 4 H++ 4 e-

at the cathode O2+ 4 H++ 4 e-→ 2 H2O

The resulting overall electrochemical reaction is:

O2+ 2 H2→ 2 H2O

What is an hydrogen fuel cell?

AXANE develops reliable and high-performance products

Stacks: carbon and metal

Why choose one technology over another for the development of your fuel cell? The field of application, as well as the environmental constraints, may be determining factors in your choice.

Carbon technology

应用程序: |

金属技术

Application: |

碳:客户福利

|

METAL : CUSTOMER BENEFITS

|

CARBON :ADVANTAGES OF AXANE'S SOLUTIONS

|

METAL :ADVANTAGES OF AXANE'S SOLUTIONS

|

Fuel cell systems

Our teams have designed and developed hundreds of systems for 20 years. Choosing AXANE for the design and development of your fuel cell system is the guarantee of benefiting from the expertise of a leader in its field.

AXANE CUSTOMER BENEFITS

|

END-USER BENEFITS

|

ADVANTAGES OF AXANE SOLUTIONS

|

由轴开发的系统和堆叠

Products - metal technology

堆栈M240Name:堆栈M240 Description:Liquid cooled metal stack for automobiles |

|

Products - carbon technology

Stack C260Name:Stack C260 Description:Liquid-cooled compact carbon stacks for heavy vehicles (trucks, buses, trains, boats) Download the堆栈C260产品表 |

|

Stack HPSName:Stack HPS Description:用于叉车和固定发电机的液冷碳堆叠 |

|

Stack G1Name:Stack G1 Description:Liquid-cooled carbon stack for stationary and portable applications |

|

索系统

HyES generatorName:HyES-G1 Dimensions:280 x 112 x 105 cm |

|

GaEL generatorName:GaEL Dimensions:940 x 450 x 385 mm |

|